Result

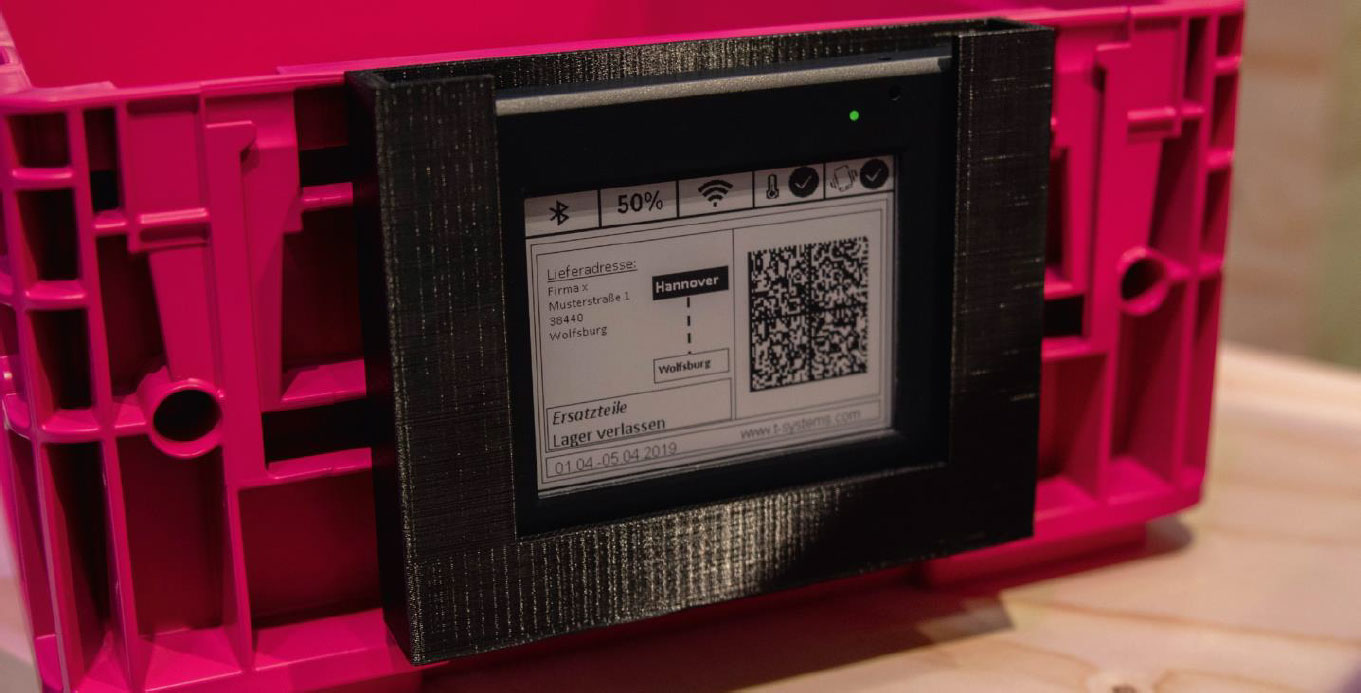

The project led to the development of prototypes with different screen sizes. Successful proof-of-concepts were conducted using these prototypes.

Digital Label & Goods Tracking means increased transparency, as goods can be precisely tracked at any time, less downtime due to quality (damage detection), and monitoring the condition of raw materials, parts, or goods.

The ability to integrate with warehouse management systems through standardized interfaces results in increased efficiency throughout the supply chain.

Material and personnel costs decrease, and the allocation of space for storage from different suppliers can be done more efficiently. Digital Label & Goods Tracking helps avoid production stoppages, enabling time savings and improved just-in-time delivery.